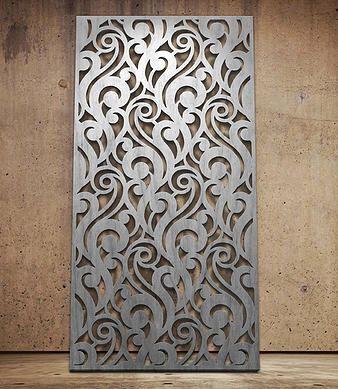

For the last few years, laser cut railings have been used by architects in villas, restaurants, hotels, etc. as stair and gallery railings, as well as visual panels. It is a different application that has started to be used indoors and outdoors, on garden walls. We create the desired pattern with laser cutting and assemble it in place after electrostatic powder coating. The material we use can be steel sheet, stainless sheet or brass sheet, depending on our customer's request and intended use.

Laser cut railings are railings produced by applying laser cutting process to metal with CNC machines. CNS cutting technology allows creating the most complex motifs and using materials that are difficult to cut. It is also known as laser cut railing. It is preferred in all areas where it is used and needed, such as balconies, gardens and stairs. They are patterned, complementary and stylish products that are used not only in homes but also in places such as cafes, seaside and restaurants.

What is Laser Cut Railing?

Laser cut railings are products that are produced by hammering iron with high temperatures of fire. Nowadays, it is possible to create more customized works with modern designs. These designs have become easier, more economical and of higher quality with CNC metal laser cutting machines. Dimensions are determined through CNC metal laser cutting machines, and then designs are drawn on the computer. These designs are then drawn and are handrails produced flawlessly and burr-free after laser cutting with CNC laser cutting machines.

Why Should We Use Laser Cut Railing?

One of the reasons why laser cut railings are widely used is the abundance of colors and patterns and the abundance of equipment suitable for these patterns. This apparatus can produce models with unlimited options in colors and patterns. You can choose a model in the pattern you want and have it made. Laser cut balcony railing models are most commonly in the form of round pipes. The reason for this is that it is easy to install and its cost is affordable. However, there are also models with wooden handles and glass. Laser cut stainless railing models are mostly used on French balconies, stairs and many other areas. Production can be made specifically for the location.

What are Laser Cut Railing Models?

Laser cut railings are the most preferred models. It has a modern and stylish stance. It is safe and sound. It has a structure that blocks air and light. Therefore, it is used in many areas. Laser cut wall mounted railings are produced in accordance with the desired model. These railings are modern and stylish products compared to normal railings. Model drawing is available upon request.

Laser cut stair railings are the most used products due to their aesthetic and stylish appearance. CNC laser cut stair railings are used indoors and outdoors, especially in buildings such as homes, business centers, restaurants and hotels. In addition to being durable, they are also products that attract attention with their stylish appearance. Laser cut railings also attract attention with their models that match decorative railings such as metal, wooden stairs and glass stairs.

What are the Advantages of Laser Cut Railing?

- Aesthetic and Elegant Appearance: Laser cutting technology enables the creation of complex and aesthetic designs. Laser-cut railings add a modern and stylish look to spaces.

- Customizability: Laser-cut railings offer customizable design options. You can use desired patterns, shapes, or details in laser-cut railings, adding a unique touch to your space.

- Precision: Laser-cut railing models are highly precise, allowing even complex or intricate designs to be cut with high accuracy.

- Durability: Laser-cut railings are typically made from durable metals, such as stainless steel, ensuring longevity and resistance to outdoor conditions.

- Lightweight and Portable: Railings produced by laser cutting can be lightweight, enhancing their portability. This facilitates easier installation and replacement processes.

- Easy Maintenance: Laser-cut railings usually feature flat surfaces, making them easy to clean with minimal accumulation of dirt and dust.

- Environmentally Friendly: Laser cutting minimizes material waste, making it an eco-friendly manufacturing method, which is advantageous for sustainability.

- Safety and Reliability: Laser-cut railings can meet high safety standards. When durable materials are used, these railings are resilient against external factors.

Laser-cut railing designs and projects are a preferred option, especially in spaces where architectural design is crucial. They provide an excellent means to bring customized designs like intricate details, patterns, or logos to life.